Semi-Automated

SPE – Solid Phase Extraction

AutoSPE – Programmable Solid Phase Extraction▼ Drugs of Abuse Sample Prep▼ Oil & Grease Extraction▼ Automated SPE – Water Analysis▼ EZSPE – Semi-Automated SPE▼ EzSPE Applications▼

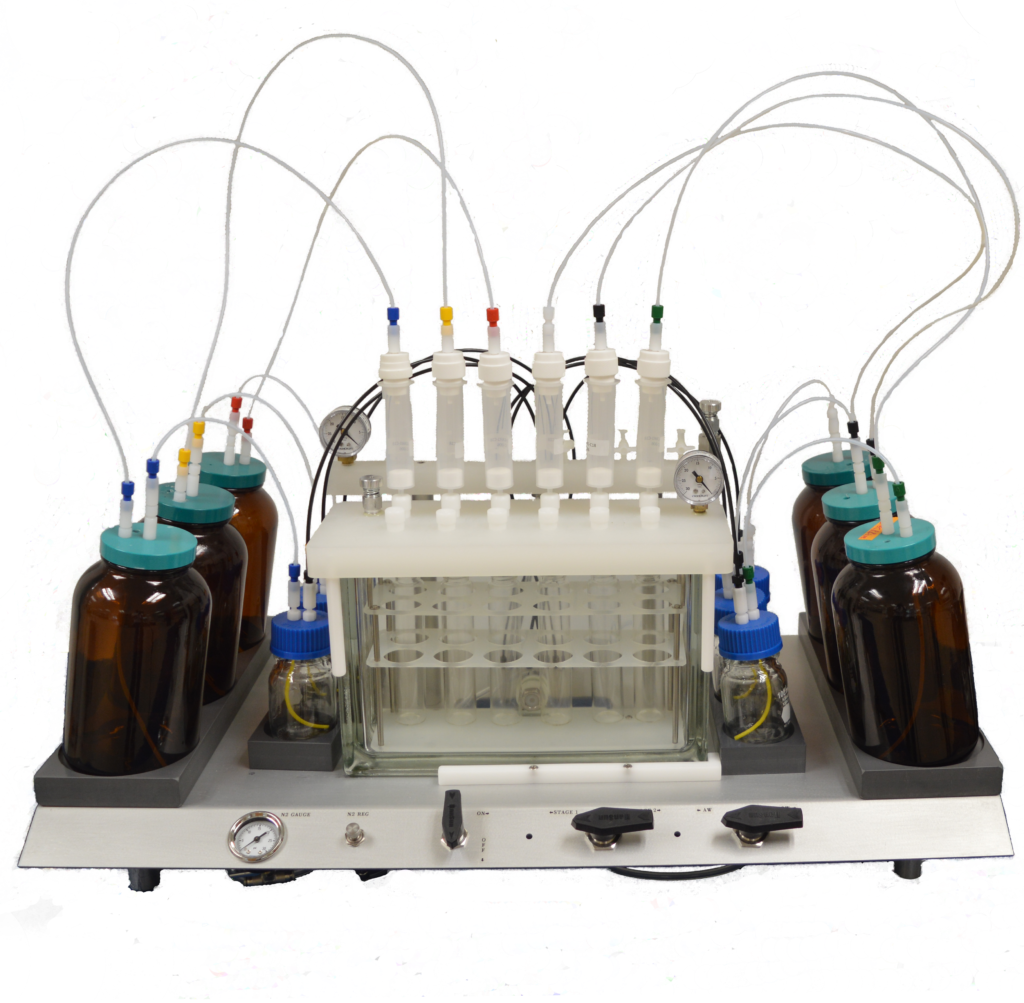

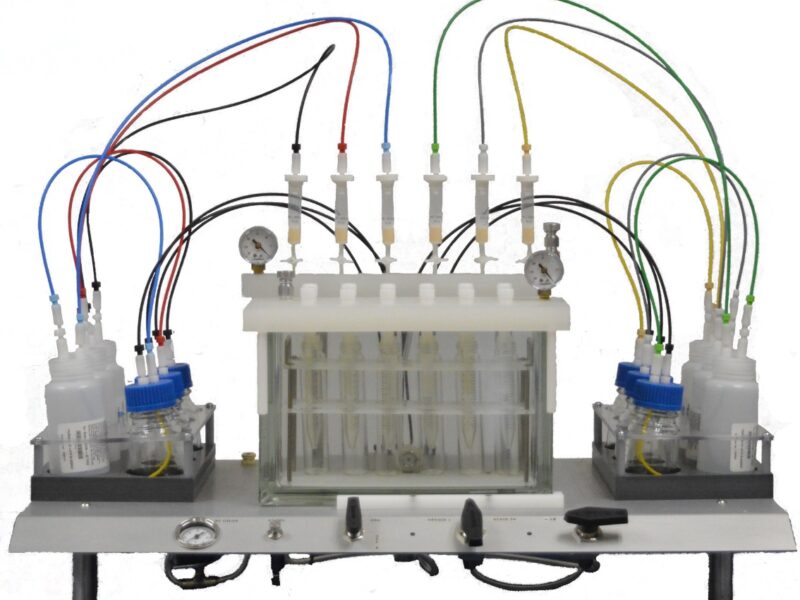

EZSPE

Semi-Automated Solid Phase Extraction System

Semi-Automated Solid Phase Extraction – EZSPE System

Semi-automated solid phase extraction offers a reliable and efficient method for sample preparation in water and wastewater analysis. The EZSPE system simplifies SPE workflows by automating key steps, helping laboratories improve consistency and reduce manual labor.

Using vacuum and nitrogen, the EZSPE automatically loads up to 12 samples and performs semi-automated solid phase extraction with speed and precision. After an initial drying step, it rinses sample bottles and delivers solvent to the SPE cartridges to extract analytes of interest. The extract is then dried using a sodium sulfate cartridge to remove residual moisture. Final extracts are collected directly into GC vials, ready for concentration using the FMS SuperVap® system.

For method reference, see the EPA’s official guidance on solid phase extraction (Method 3535A).

Applications:

Drinking Water

Waste Water

Juice

Key Features

Quick & Easy Operation: No computer, electronics, or software required

High Throughput: Process 6 to 12 samples in parallel in under 30 minutes

Reliable Design: No electronic or mechanical components to fail

Low Solvent Usage: Uses as little as 50 mL per sample

Certified Consumables: Works with FMS-certified SPE cartridges for guaranteed performance

Flexible Cartridge Support: Compatible with all standard SPE cartridge sizes

Effective Drying: Dual-stage drying with vacuum and nitrogen

In-Line Drying: Sodium sulfate cartridge removes residual moisture inline

Automated Bottle Rinse: Ensures maximum analyte recovery

Cost-Effective: No capital equipment investment required

Semi-Automated Solid Phase Extraction

Using vacuum & nitrogen, the EZSpe automatically loads 12 samples and performs the solid phase extraction quickly using the vacuum pump. After the first drying step, the EZSpe rinses the sample bottles and delivers the solvent to the SPE cartridges to extract analytes of interest. The extracts are then dried using a sodium sulfate cartridge to remove all water from the final extract which can be delivered directly to the direct GC vial vessel, ready for the final concentration in the FMS SuperVap®.

The ultimate rewards are saving labor and time

Applications:

Drinking Water

Waste Water

Juice

Key Features

Quick & Easy Operation: No computer, electronics, or software required

High Throughput: Process 6 to 12 samples in parallel in under 30 minutes

Reliable Design: No electronic or mechanical components to fail

Low Solvent Usage: Uses as little as 50 mL per sample

Certified Consumables: Works with FMS-certified SPE cartridges for guaranteed performance

Flexible Cartridge Support: Compatible with all standard SPE cartridge sizes

Effective Drying: Dual-stage drying with vacuum and nitrogen

In-Line Drying: Sodium sulfate cartridge removes residual moisture inline

Automated Bottle Rinse: Ensures maximum analyte recovery

Cost-Effective: No capital equipment investment required